Menu

Close menu

>>>

QA/QC Quality Assurance Quality Control

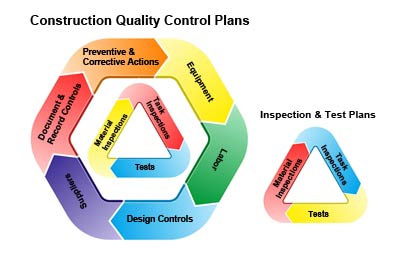

Overview: The system of QA/QC (Quality Assurance/ Quality Control) was initially introduced in World War II when munitions were inspected and tested for defects after manufactured. Today's QA/QC systems emphasize catching defects before completing work or before final product.

Overview: The system of QA/QC (Quality Assurance/ Quality Control) was initially introduced in World War II when munitions were inspected and tested for defects after manufactured. Today's QA/QC systems emphasize catching defects before completing work or before final product.

As definition QA/QC is the combination of quality assurance, (the process or set of processes used to measure and assure the quality of a product),

and quality control, the process of ensuring products and services meet consumer expectations).[1] Quality assurance is process oriented and focuses on defect prevention, while quality control is product oriented and focuses on defect identification. QA/QC inspectors task to protect the consumer from defective products. In testing process inspector has the option many options (1) fixing the problem by himself. (2) To return the product back for repairs. (3) To tag the product for rejection. we understand the important of QA/QC, and we always recommend our clients to give big attention to QA/QC task and develop separate department devoted to QA/QC system targeting to increase credibility, improve work processes and work efficiency. We shall provide inspectors of client with a complete process to do his task properly.

When important issues arise, the inspector shall notifies supervisors and works with them to correct the problem.